New evidence from Bangladesh shows that aligning business owners' profit motives with environmental and health goals can effectively reduce the harm caused by pollution from brick kilns.

Editor’s note: For a broader synthesis of themes covered in this article, check out our VoxDevLit on Climate Adaptation.

Air pollution is the second largest risk factor for deaths globally, with a disproportionate burden of death in South Asia (IHME 2021). Coal-fired brick manufacturing is one of the largest sources of air pollution and greenhouse gas emissions in the region, producing particulate matter with a diameter of less than 2.5 microns (PM2.5) that negatively impacts health (Brooks et al. 2023, Haque et al. 2018, Sherris et al. 2021, Jahan 2025). Bangladesh has witnessed some of the largest increases in both PM2.5 and pollution-related deaths in recent years (IHME 2021, Apte et al. 2018), with the brick industry playing an important role as highly polluting kilns have proliferated.

While there are regulations on brick kilns, in practice these have been weakly enforced (Brooks et al. 2024, Lee et al. 2021, Khaliquzzaman et al. 2020). For example, 77% of kilns in Bangladesh are illegally located within one kilometre of a school (Lee et al. 2021). The other dominant approach to mitigating these harms has been the promotion of technologically advanced kilns, which are substantially more expensive to construct and operate than traditional kilns (Brooks et al. 2024, Khaliquzzaman et al. 2020). Consequently, these expensive kilns have not diffused and produce less than 7% of the bricks in the market (Alam and Barman 2019). Zigzag kilns, a type of traditional kiln that is deemed ‘environmentally friendly’ by the Department of Environment, produce more than 65% of bricks in Bangladesh, but are mostly constructed and operated incorrectly, thereby not achieving their efficiency potential.

With annual production estimated at 35 billion bricks per year, the brick industry produces essential construction materials for Bangladesh’s developing and urbanising economy; demand for bricks is thus projected to grow (Alam and Barman 2019, Khaliquzzaman et al. 2020). At the same time, new strategies to reduce the environmental and public health harm from brick kilns are urgently needed. In our research, we explore whether increasing energy efficiency of traditional brick kiln operation can be a practical and cost-effective solution (Brooks et al. 2025).

Figure 1: Example of a typical zigzag brick kiln in Bangladesh

Source: Sushanta Kumar Paul

Delivering an effective brick kiln energy-efficiency intervention

We conducted a randomised control trial during the November 2022 to May 2023 brick firing season with 276 traditional zigzag kilns across six districts of Khulna Division, Bangladesh. Our experiment had three arms: a control arm, a ‘technical’ arm, in which kilns received information, training, and technical support on how to improve efficiency and reduce emissions within operations, and a ‘technical + incentive information’ arm (technical+), in which kilns also received messaging on the business rationale for offering financial or nonfinancial (e.g. rest areas, clothing, meals) incentives encouraging workers to adopt the new operational methods, in addition to technical training and support. The technical intervention (which we refer to as Zigzag 2.0) focused on two key operational improvements: (1) continuous fuel feeding by a single fireman, and (2) less dense brick stacking (in addition to several other components), which were refined after a year of piloting (Brooks et al. 2024). These practices improve fuel combustion and reduce heat loss, which should improve efficiency and reduce emissions, as well as improve brick quality and reduce fuel expenditures.

The technical training was delivered to owners, managers, supervisors, and key workers at every kiln in the two intervention arms through a mix of classroom and on-site sessions. Our technical team provided ongoing technical support to intervention kilns throughout the season to reinforce the training and help troubleshoot difficulties. The messaging in the technical+ arm was also reinforced with follow-up visits to kilns during the season.

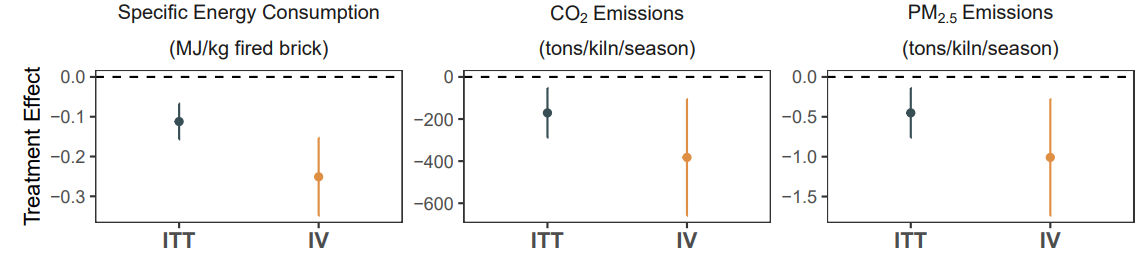

Kiln owners enthusiastically adopted improved practices

Across both intervention arms, 65% of kilns adopted the two key practices (improved fuel feeding and brick stacking). Strikingly, we found that 20% of control kilns also adopted the intervention, as all participants were aware of the Zigzag 2.0 as part of study enrolment and some owners in the control group wanted to learn Zigzag 2.0 sooner, despite our promise to return the following season. The control kilns that independently implemented the improved practices either learned from treatment kilns or managed to avail themselves of some training in their district. Moreover, upon returning during the following firing season, we found that adoption not only sustained but also increased in all three arms. Together, this represents strong revealed preference evidence of the demand for Zigzag 2.0 from kiln owners and is encouraging for scaling efforts (which we are currently exploring).

Figure 2: Adoption of Zigzag 2.0

Note: This figure presents adoption of the Zigzag 2.0 technical intervention across study arms and over time.

Zigzag 2.0 reduced emissions, while delivering economic benefits to kiln owners

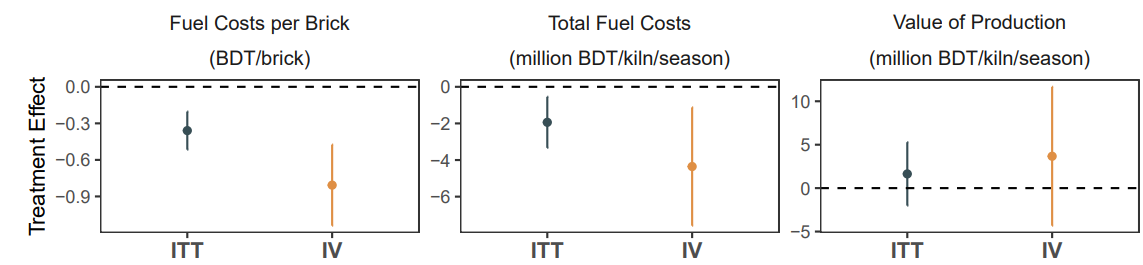

We conducted extensive kiln performance monitoring to measure fuel use and brick production during a 24- to 36-hour period. Zigzag 2.0 reduced the amount of energy used to fire one kilogram of bricks by 11% (or 25% among compliers). This increased energy efficiency reduced CO2 and PM2.5 emissions: 171-382 tons of CO2 emissions and 0.45 to 1 ton of PM2.5 emissions were averted per kiln over the season.

Kiln owners saw an 8% increase in the proportion of highest quality bricks they produced, as well as a 10% decrease in fuel spending per brick (18% and 22% among compliers, respectively), which is their most expensive business input.

Figure 3: Impact of Zigzag 2.0 on energy, emissions, and economic outcomes

Panel A: Energy and emissions

Panel B: Economic outcomes

Notes: Panel A presents the intervention’s impact on outcomes related to energy use and emissions. Panel B reports the findings for economic outcomes for kiln owners. Both panels show regression results for the intention-to-treat (ITT) and instrumental variable (IV) specifications for a different outcome. The ITT specification, shown on the left in dark grey, bundles both treatment arms. The IV specification, shown on the right in orange, uses random assignment to either treatment arm as an instrument for adopting the technical intervention, and can be interpreted as the effect of adopting the intervention on a given outcome. Both specifications include randomization strata fixed effects and estimated heteroskedasticity-robust standard errors. In each panel, coefficients are denoted by dots and vertical bars represent 95% confidence intervals around the regression coefficient.

The social benefits of improving kilns’ energy efficiency

The primary cost of the randomised controlled trial was the training expense and technical support throughout the season, which came to USD$486 per treatment kiln. We valued the societal benefits of reduced CO2 emissions using a social cost of carbon of $185/ton (Rennert et al. 2022), and find the social benefits outweigh costs by 65 to 1 (with a conservative estimate of 20 to 1). The social cost of carbon does not account for the negative health impacts of PM2.5, which are therefore excluded from our cost-benefit calculation but if included would make the ratio more favourable. Overall, CO2 emissions reductions were achieved at a low cost of $2.85/ton and without any evidence of rebound effects.

Key takeaway: Improved operational practices could be a win-win for kiln owners and the environment

We show promising results for a win-win strategy for cleaner brick production with a low-cost intervention that was achieved without any capital investment from kiln owners or regulatory enforcement from the state. At the same time, it is important to note that the technical plus incentive information arm had no differential impact on adoption; there is also no evidence that kiln owners in that arm used any of the suggested incentives. Given that kiln workers are a vulnerable and exploited population, we will continue to explore possible incentive-compatible strategies for improving work conditions.

Our approach demonstrates how aligning profit motives with environmental and health improvements offers a promising path for some industries in weak regulatory states. Moving forward, we plan to scale Zigzag 2.0 across Bangladesh and eventually to other countries in South Asia where brick production is similar.

References

Apte, J S, M Brauer, A J Cohen, M Ezzati, and C A Pope (2018), “Ambient PM2.5 reduces global and regional life expectancy”, Environmental Science & Technology Letters, 5(9): 546–551.

Blackman, A (2000), “Informal sector pollution control: What policy options do we have?”, World Development, 28(12): 2067–2082.

Brooks, N, D Biswas, S Maithel, G Miller, A Mahajan, M R Uddin, S Ahmed, M Mazab, M Rahman, and S P Luby (2025), “Reducing emissions and air pollution from the informal sector: Evidence from Bangladesh”, Science, 388: eadr7394.

Brooks, N, D Biswas, S Maithel, S Kumar, M R Uddin, S Ahmed, M Mahzab, G Miller, M Rahman, and S P Luby (2024), “Building blocks of change: The energy, health, and climate co-benefits of more efficient brickmaking in Bangladesh”, Energy Research & Social Science, 117: 103738.

Brooks, N, D Biswas, R Hossin, A Yu, S Saha, S Saha, S K Saha, and S P Luby (2023), “Health consequences of small-scale industrial pollution: Evidence from the brick sector in Bangladesh”, World Development, 170: 106318.

Haque, M I, K Nahar, M H Kabir, and A Salam (2018), “Particulate black carbon and gaseous emission from brick kilns in Greater Dhaka region, Bangladesh”, Air Quality, Atmosphere & Health, 11(8): 925–935.

Institute for Health Metrics and Evaluation (IHME) (2024), "Global Burden of Disease 2021: Findings from the GBD 2021 Study".

Jahan, N (2025), “Climate adaptation in Bangladesh”, VoxDev.

Khaliquzzaman, M, A S Harinath, S A Ferdousi, and S M M H Khan (2020), “Thirty years’ quest for emission reduction and energy efficiency improvement of brick kilns in Bangladesh”, International Journal of Environmental Monitoring and Analysis, 8(1), Article 1.

Lee, J, N R Brooks, F Tajwar, M Burke, S Ermon, D B Lobell, D Biswas, and S P Luby (2021), “Scalable deep learning to identify brick kilns and aid regulatory capacity”, Proceedings of the National Academy of Sciences, 118(17): e2018863118.

Rennert, K, F Errickson, B C Prest, L Rennels, R G Newell, W Pizer, C Kingdon, J Wingenroth, R Cooke, B Parthum, D Smith, K Cromar, D Diaz, F C Moore, U K Müller, R J Plevin, A E Raftery, H Ševčíková, H Sheets, J H Stock, T Tan, M Watson, T E Wong, and D Anthoff (2022), “Comprehensive evidence implies a higher social cost of CO2”, Nature, 610: 687–692.

Sherris, A R, B A Begum, M Baiocchi, D Goswami, P K Hopke, W A Brooks, and S P Luby (2021), “Associations between ambient fine particulate matter and child respiratory infection: The role of particulate matter source composition in Dhaka, Bangladesh”, Environmental Pollution, 290: 118073.